About Asmik

Asmik is a high-tech enterprise specializing in the research, development, production, and service of automated sensing technologies. Main products: include flowmeters, pressure meters, level meters, and analytical instruments. With its outstanding R&D capabilities, superior product quality, high cost-effectiveness, and fast delivery, Asmik has won the recognition of numerous international brands ( TOTO & Ford Motor ) and established more stable cooperative relationships.

It possesses a CNAS-certified laboratory of over 1500 m² and 2 industry-leading SMT production lines, with an annual production capacity exceeding 600,000 industrial instruments.

Our products have obtained multiple certifications including CE, ISO, and UL, and undergo more than 24 internal quality control processes.

The company's overseas headquarters are located in Singapore, with more than ten offices worldwide. Its customers are located in more than 160 countries and regions across North America, Europe, South America, and Asia.

Asmik In Figures

Asmik is committed to process automation sensors and instruments

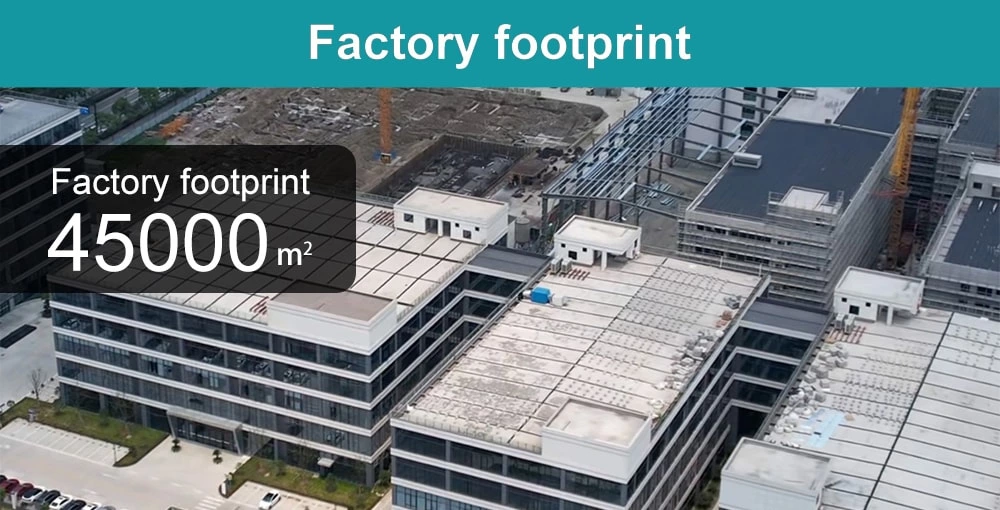

45000+m2

Modern factory

600+

Skilled Employees

20+

Years experience

160+

Countries business

Smart manufacturing

Intelligent, modern factories enable efficient production. Contact us!

AsmiK's Six-Step

Quality Management System

Quality control is the most crucial aspect of the production process for process automation instruments. Asmik places great emphasis on quality control, and we conduct rigorous inspections on every batch of goods destined for destinations worldwide, adhering to international inspection standards.

Six Steps To Get A Process Automation Instruments Sample

01 Collect Sample Information

Please tell us which instrument you need and its application scenario to ensure the sample is suitable

02 Selection Confirmation

Confirmation of instrument model and communication of technical solutions to ensure sample accuracy.

03 Charge For Samples & Making

Determine the sample cost plan based on the required samples.

04 Check The Production

When the factory starts to produce samples, we will go to the factory to check and make sure the production is running smoothly.

05 Check & Test samples

After receiving the sample, we will check and test for defects. After confirming the sample, we will send the sample by express.

06 Notify The Customer

After the samples are sent, we will send an email to the customer with the courier bill number and sample photos.