Specification

Introduction

The FCC800 Marine-Grade Coriolis Mass Flow Meter represents the next generation of process instrumentation, specifically calibrated for the harsh realities of maritime and heavy industrial operations. Unlike traditional volumetric meters that struggle with pressure changes, the FCC800 provides true mass flow readings, ensuring your data remains unaffected by fluctuating fluid properties.

Designed to be the backbone of fuel efficiency and process integrity, this sensor combines laboratory-grade precision with an industrial-strength enclosure. Whether you are monitoring bunker fuel viscosity on a vessel or managing aggressive chemical dosing in a plant, the FCC800 delivers the critical, multi-parameter data needed to optimize performance and reduce waste.

Working principle

The FCC800 utilizes the Coriolis principle to turn fluid mechanics into actionable data:

-

Resonant Oscillation: The flow tubes are energized to vibrate at a precise natural frequency.

-

Inertial Phase Shift: As media travels through the vibrating tubes, inertia causes a measurable twist (phase shift) in the tube's motion. This shift is directly correlated to the mass flow rate.

-

Frequency Analysis: The frequency of the tube's vibration changes with the fluid's mass, allowing the device to instantly calculate density.

-

Real-Time Computation: Onboard electronics decode these physical shifts into digital values for flow, density, and temperature, transmitting them instantly to your control room.

Key features

To simplify installation and meet regulatory compliance, this meter offers a suite of benefits designed to maximize uptime and measurement confidence:

1. Comprehensive Multi-Variable Analysis

The FCC800 Coriolis meter acts as an all-in-one station, concurrently monitoring mass flow, volume, medium density, and temperature, which eliminates the need for separate density meters and temperature sensors.

2. Engineered for Extreme Environments

With an IP67-rated housing and advanced vibration decoupling, this FCC800 lineup ensures stable readings even amidst the mechanical noise of ship engines or high-pressure pumping stations.

3. Universal Media Handling

From non-conductive fluids and viscous heavy oils to slurries containing suspended solids, this meter handles complex media that would clog or confuse other technologies. It is equally effective for gas measurement applications.

4. Zero-Maintenance Design

With no moving parts to wear out and no internal obstructions to trap debris, the FCC800 dramatically lowers operational costs. Its non-intrusive design ensures a long lifecycle with minimal downtime.

5. Installation Flexibility

The FCC800 requires no flow conditioning, meaning you don't need long straight pipe runs before or after the meter. It fits directly into tight piping layouts without sacrificing accuracy.

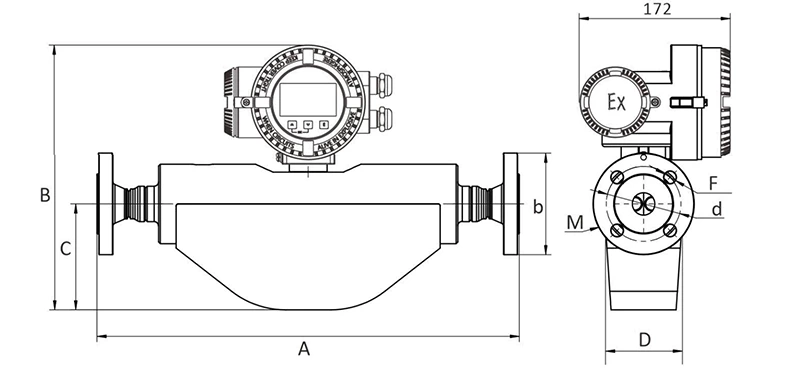

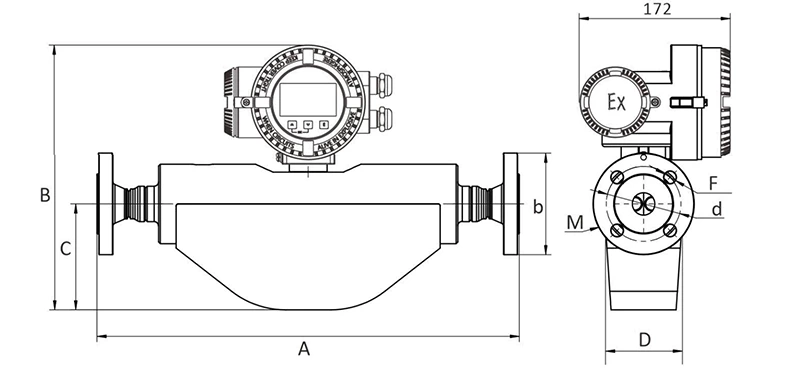

Specification

| Measured variables |

Mass flow rate, density, temperature |

| Measuring medium |

Gases, liquids, slurries, suspensions, etc |

| Nominal diameter |

U-shaped type: DN3~DN150

Micro-bend type: DN8~DN100

Straight pipe type: DN8~DN50

Inverted triangle type: DN1~DN2 |

| Range ratio |

U-shaped type: 10:1

Micro-bend type: 10:1

Straight pipe type: 5:1

Inverted triangle type: 10:1 |

| Temperature measurement range |

(-240~350)℃ |

| Accuracy |

Flow volume: Level 0.15, Level 0.2, Level 0.5

Density: ±0.001g /cm³ ( ± 1kg / m³ )

Temperature: ± 1 ℃ or ± 0.5% × test value, whichever is greater. |

| Repeatability |

1/2 of the accuracy |

| Transmitter output |

(4~20) mA, load resistance ≤ 750Ω |

| Communication |

RS485 , MODBUS-RTU;Hart |

| Pulse output |

Duty cycle: 10%~90%

Pulse frequency: Maximum 10000Hz

Active: Output current 10mA, open circuit voltage 30V |

| Power supply |

24VDC/220VAC |

| Power consumption |

≤ 10W |

| Nominal pressure |

Clamp connection type: Pressure resistant PN16

Flange connection type: pressure resistant PN16, PN40, or PN63 |

| Ambient temperature |

( -40~55 ) ℃ (with display: -25 ℃~ 55 ℃) |

| humidity |

≤95% |

| Protection level |

IP67 |

Applications

The FCC800 is the preferred choice for sectors where accuracy directly impacts the bottom line:

- Maritime Fuel Management: Essential for bunker delivery monitoring and fuel consumption analysis to meet environmental compliance and reduce costs.

- Chemical Processing: Delivers precise stoichiometry for reactor feeds, ensuring consistent product quality and safety.

- Pharmaceutical Production: Provides hygienic, high-accuracy measurement for active ingredients and solvents.

- Custody Transfer: High precision makes it suitable for fiscal metering where every drop counts.

- Wastewater Treatment: Reliably measures sludge and polymer dosing without clogging.

- Food & Beverage: Ensures consistent taste and texture by accurately controlling ingredient density and flow.