Specification

Asmik Coriolis effect mass flow meters provide highly accurate flow measurement for liquids and gases across industries like oil, gas, chemicals, and food production. Based on the advanced Coriolis effect and technology, Asmik Coriolis meters directly measure mass flow, density, and temperature with precision up to ±0.1%.

Asmik flow meter operates on the Coriolis principle that states the circulating air has a deflection to the right in the northern hemisphere and forward to the left in the southern hemisphere as the Earth rotates on its axis.

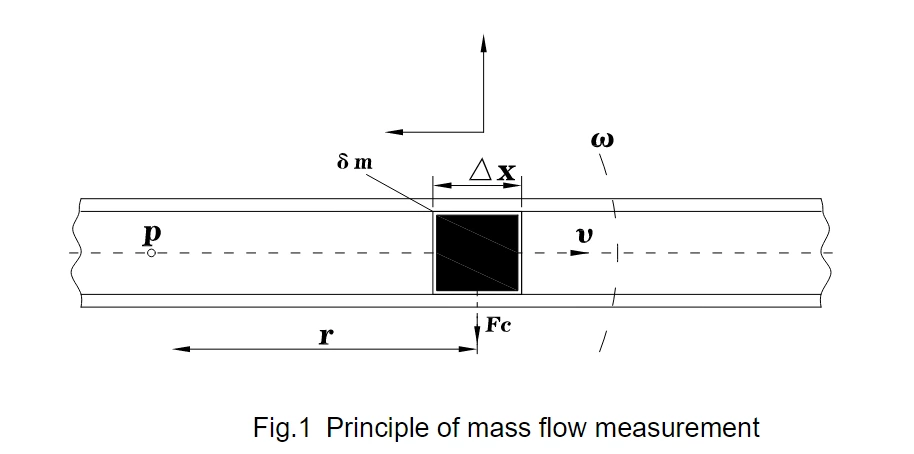

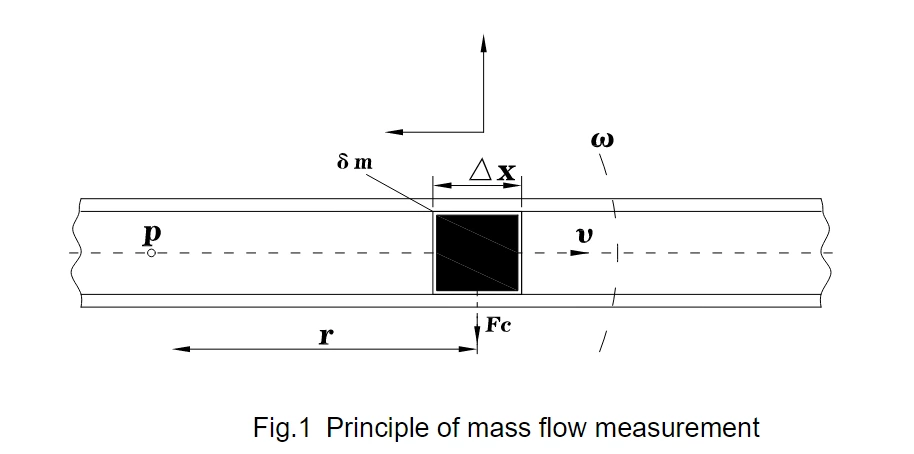

Based on this theory, the Coriolis effect mass flow sensor works in this way: if a pipe is rotated around a point (P) while the fluid is flowing through it (toward or away from the center of rotation), that fluid will generate an inertial force, as shown in Fig.1:

The particle of mass δm moves to the right in the tube at a constant speed υ, while the tube rotates around a fixed point P at an angular velocity ω. At this time, the particle will have two acceleration components:

(1) Normal acceleration αr (Centric acceleration): its value is equal to ω2r, which is directed towards point P.

(2) Tangential acceleration αt (Coriolis acceleration): whose value is equal to 2ωυ, and the direction is αr perpendicular. The force produced by the tangential acceleration is called the Coriolis force, and its value is equal to Fc=2ωυδm.

In the Fig.1 table, the fluid Δm=ρA×ΔX,

So, the Coefficient of friction can be expressed as:

ΔFc=2ωυ×δm=2ω×υ×ρ×A×ΔX=2ω×δqm×ΔX

where A is the cross-sectional area of the tube:

Δqm=δdm/dt=υρA

For a specific rotating tube, its frequency characteristics are certain; ΔFc depends only on δqm. Therefore, the mass flow can be measured directly or indirectly by measuring the Coriolis force.

For more details on how the Coriolis mass flowmeter works, please visit our manual PDF of the Coriolis effect mass flow sensor for custody, oil, gas, water, or wastewater processing.

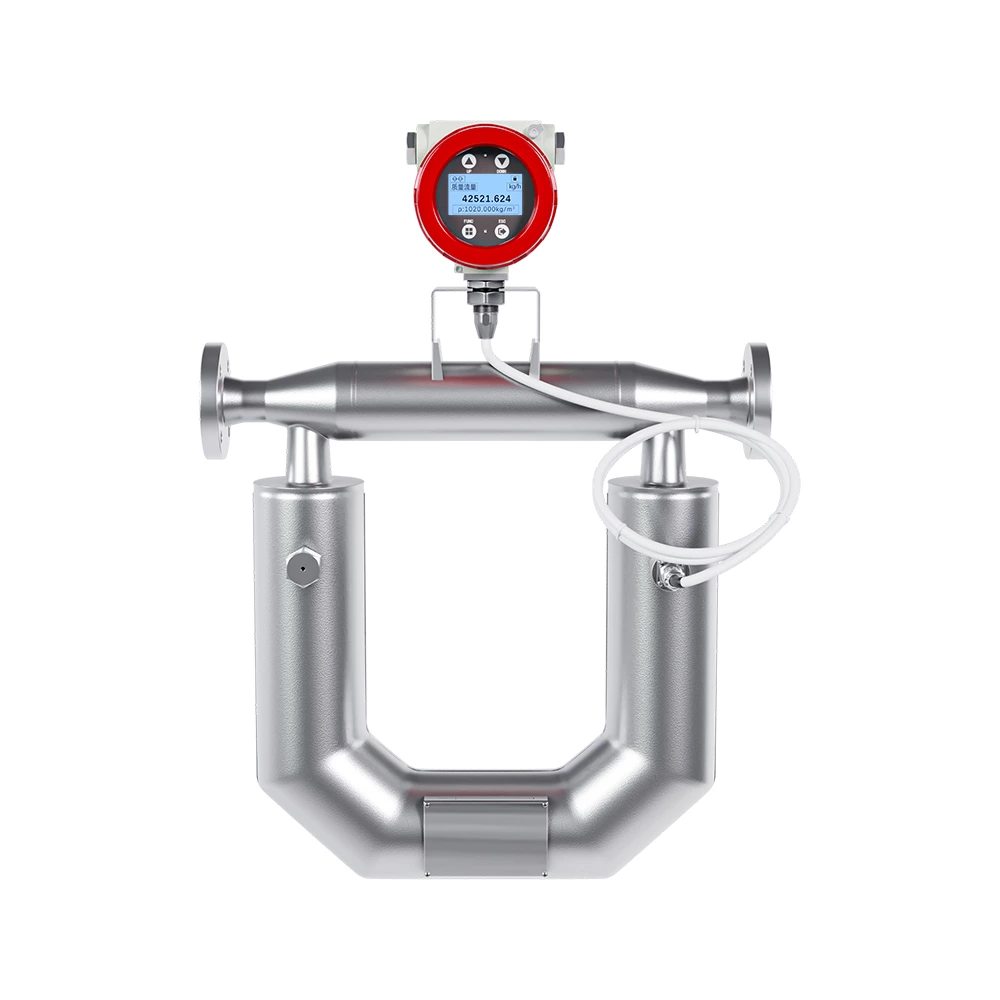

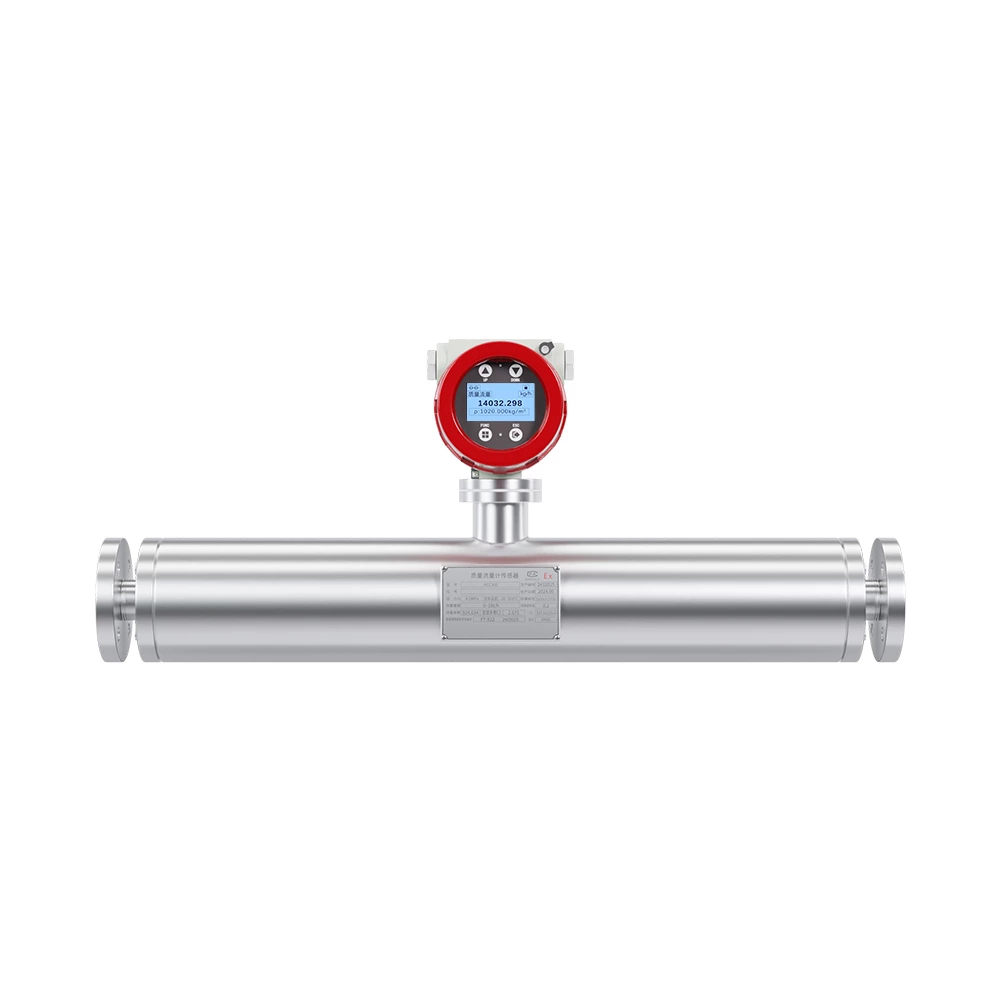

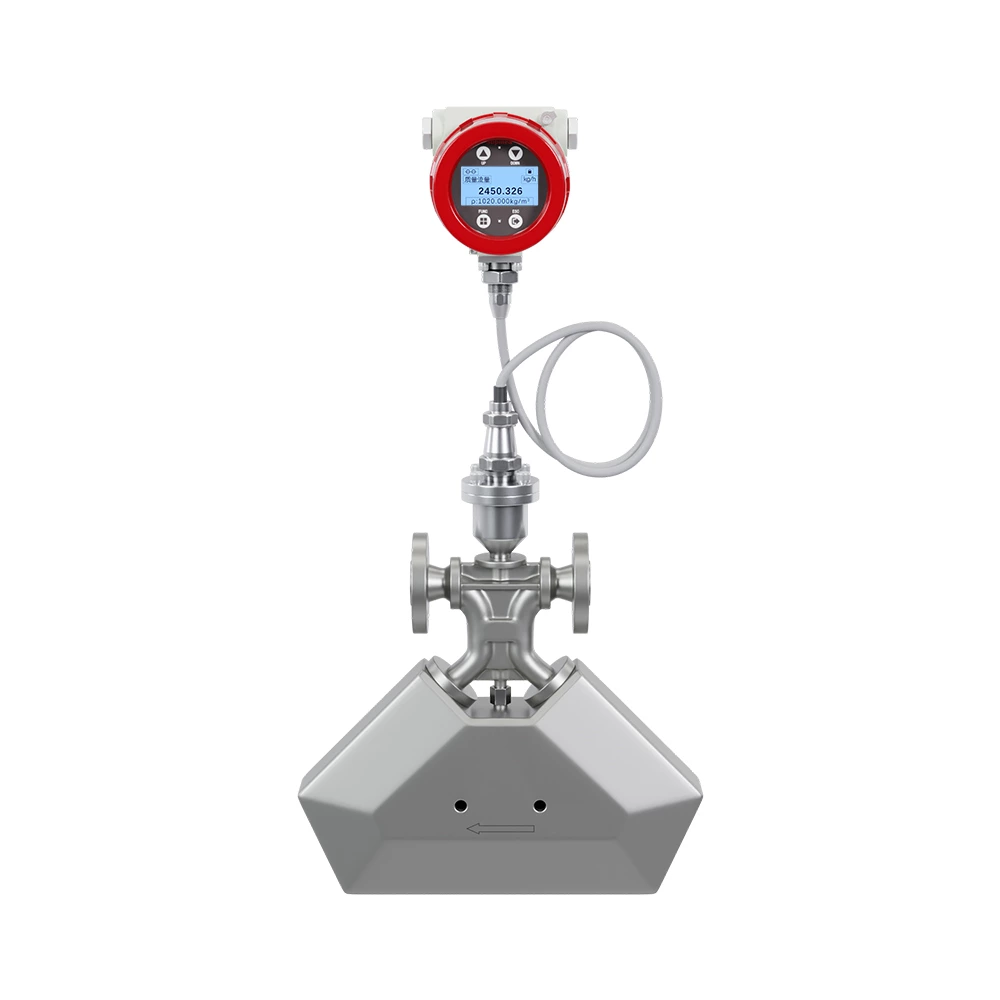

| Diameter |

U-type:DN20~DN150; Triangular:DN3~DN15; Straight Tube:DN8~DN80 |

| Measurand |

Mass flow, density, temperature |

| Density accuracy |

Earth 0.002g/cm³ |

| Accuracy |

0.1%,0.15%,0.2% |

| Temperature |

-40℃~+60℃ |

| Power consumption |

<15W |

| Power supply |

220VAC ; 24VDC |

| Signal output |

4~20mA, RS485, HART |

| Ingress protection |

IP67 |

| Density range |

(0.3~3.000)g/cm³ |

| Repeatability |

1/2 of the measurement error |

| Medium temperature |

Standard type: (-50~200)℃, (-20~200)℃; High temperature type: (-50~350)°C; Low-temperature type: (-200~200)°C |

| Process pressure |

(0~4.0)MPa |

| Humidity |

35%~95% |

| Transmission output |

(4~20) mA, output load (250~600) Ω |

SUP Coriolis mass flow meters are widely used across various industries, including oil, gas, chemical processing, food and beverage, pharmaceutical, water treatment, environmental protection, and renewable energy applications such as hydrogen and biodiesel production.