Specification

Specification

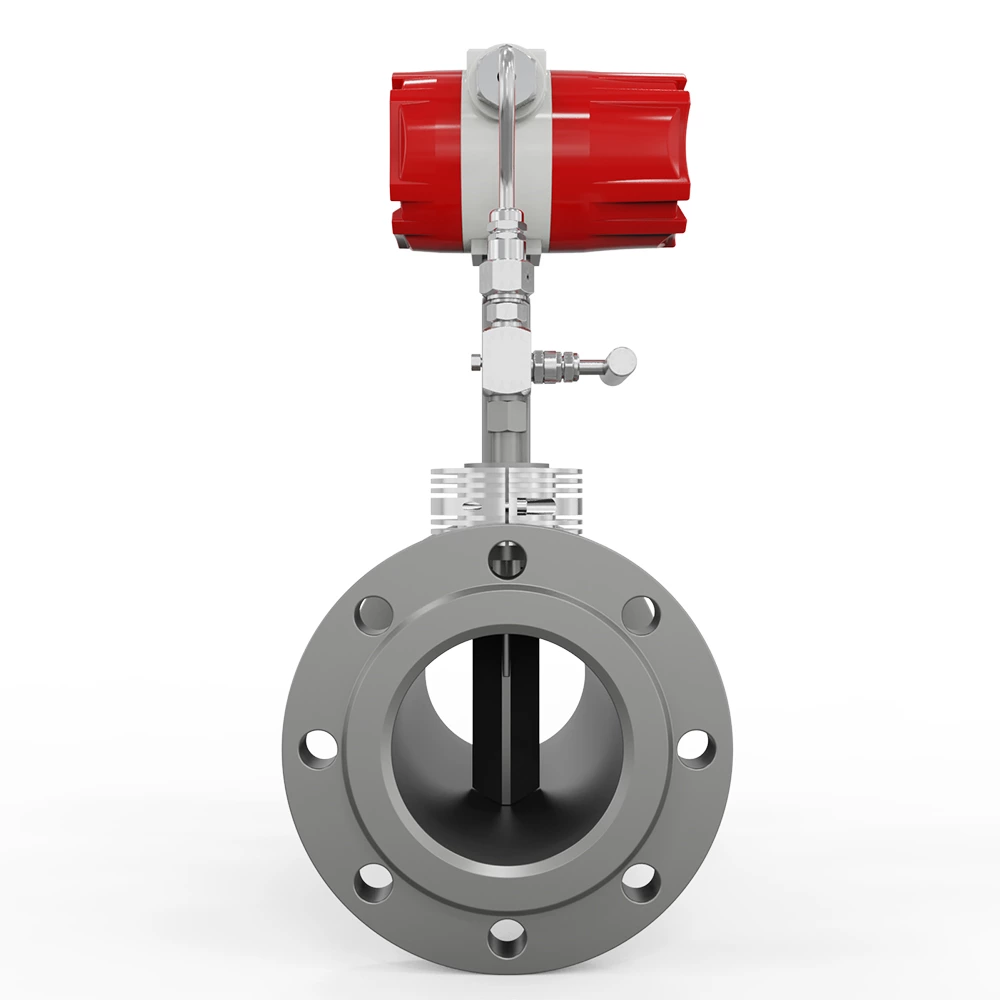

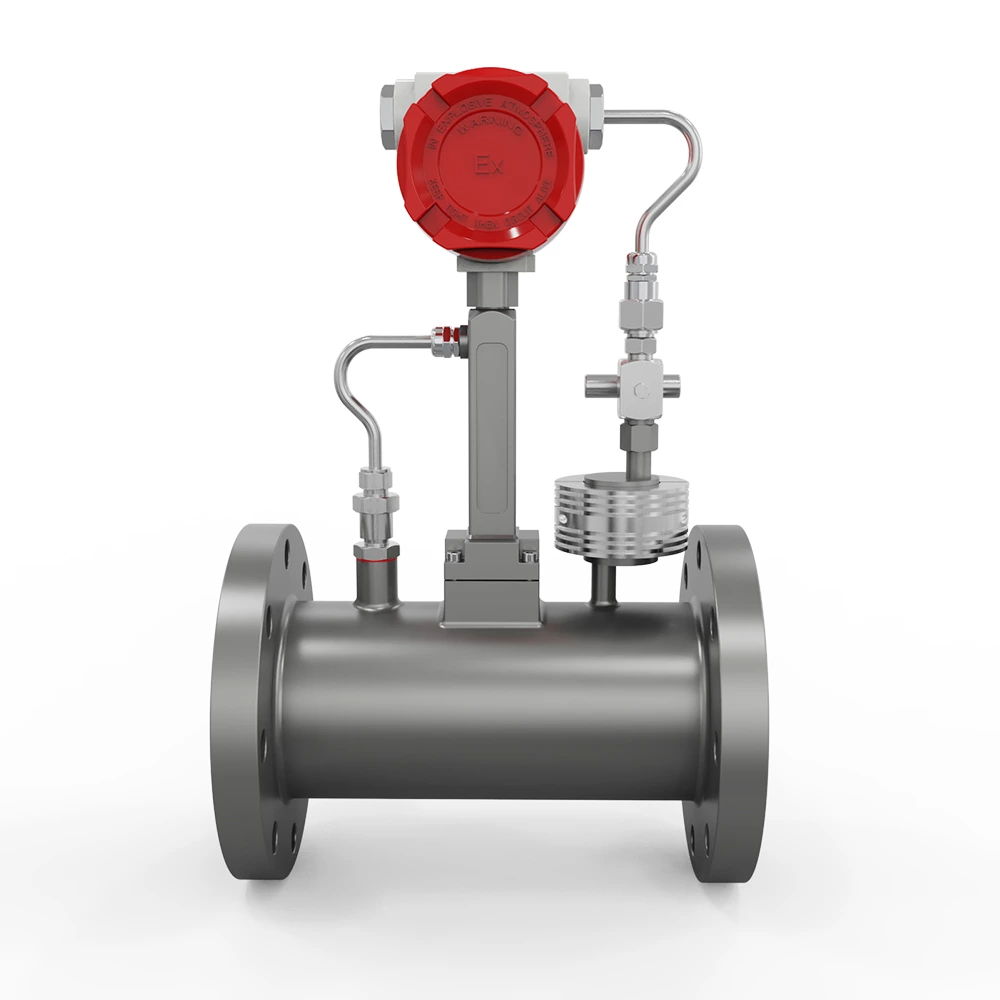

| Product |

Vortex flowmeter with temperature & pressure compensation |

| Model |

SUP-LUGB |

| Diameter nominal |

DN10~DN500 |

| Installation |

Wafer connection: DN10-DN500(priority PN2.5MPa) Flange connection: DN10-DN80(priority PN2.5MPa);DN100-DN200(priority PN1.6MPa);DN250-DN500(priority PN1.0MPa) |

| Accuracy |

1.5%, 1.0% |

| Range Ratio |

8:1 |

| Medium Temperature |

-20°C ~ +150°C, -20°C ~ +260°C, -20°C ~ +320°C, -20°C ~ +420°C |

| Output signal |

4-20mA |

| Frequency |

RS485 communication (Modbus RTU) |

| Power supply |

24VDC±5% Li battery(3.6VDC) |

| Ingress protection |

IP65 |

| Body Materials |

Stainless shell |

| Display |

128*64 dot matrix LCD |

Noted: the product strictly prohibited to be used in explosion-proof occasions.

A vortex steam flow meter is a device used to measure the flow rate of steam or other fluids in a pipe. It works by measuring the frequency of vortices created by the fluid as it passes through a bluff body in the pipe. The vortex steam flow meter is particularly useful for measuring the flow of steam in power generation plants, where accurate flow measurement is crucial for efficiency and energy savings.

The SUP-LUGB vortex steam flow meter consists of a sensor and a transmitter. The sensor has a bluff body that is placed in the pipe, causing vortices to form downstream of the body. These vortices create pressure fluctuations that are detected by a piezoelectric crystal in the sensor. The transmitter converts the piezoelectric signal into a flow rate measurement that can be used for process control.

The vortex steam flow meter is widely used in power generation plants, where it is used to optimize steam flow and energy consumption. It is also commonly used in other industrial applications such as chemical processing, oil and gas, and food and beverage production. It has several advantages over other flow measurement technologies, including high accuracy, low maintenance, and the ability to measure flows in high-temperature and pressure environments.

In summary, the vortex steam flow meter is a highly reliable and accurate device for measuring the flow rate of steam and other fluids in a pipe. Its versatility and ease of use make it a popular choice in a range of industrial applications where precise flow measurement is essential for process control and optimization.