Selecting Liner Materials: PTFE vs. PFA vs. Hard Rubber for Slurries Measurement

Slurry handling is a critical challenge across industries such as mining, wastewater treatment, chemical processing, and power generation. Unlike clean liquids, slurries contain suspended solids that introduce abrasion, corrosion, and mechanical stress simultaneously.

In this context, liner material selection is not a minor design choice; instead, it directly affects measurement accuracy, equipment lifespan, maintenance frequency, and overall process reliability.

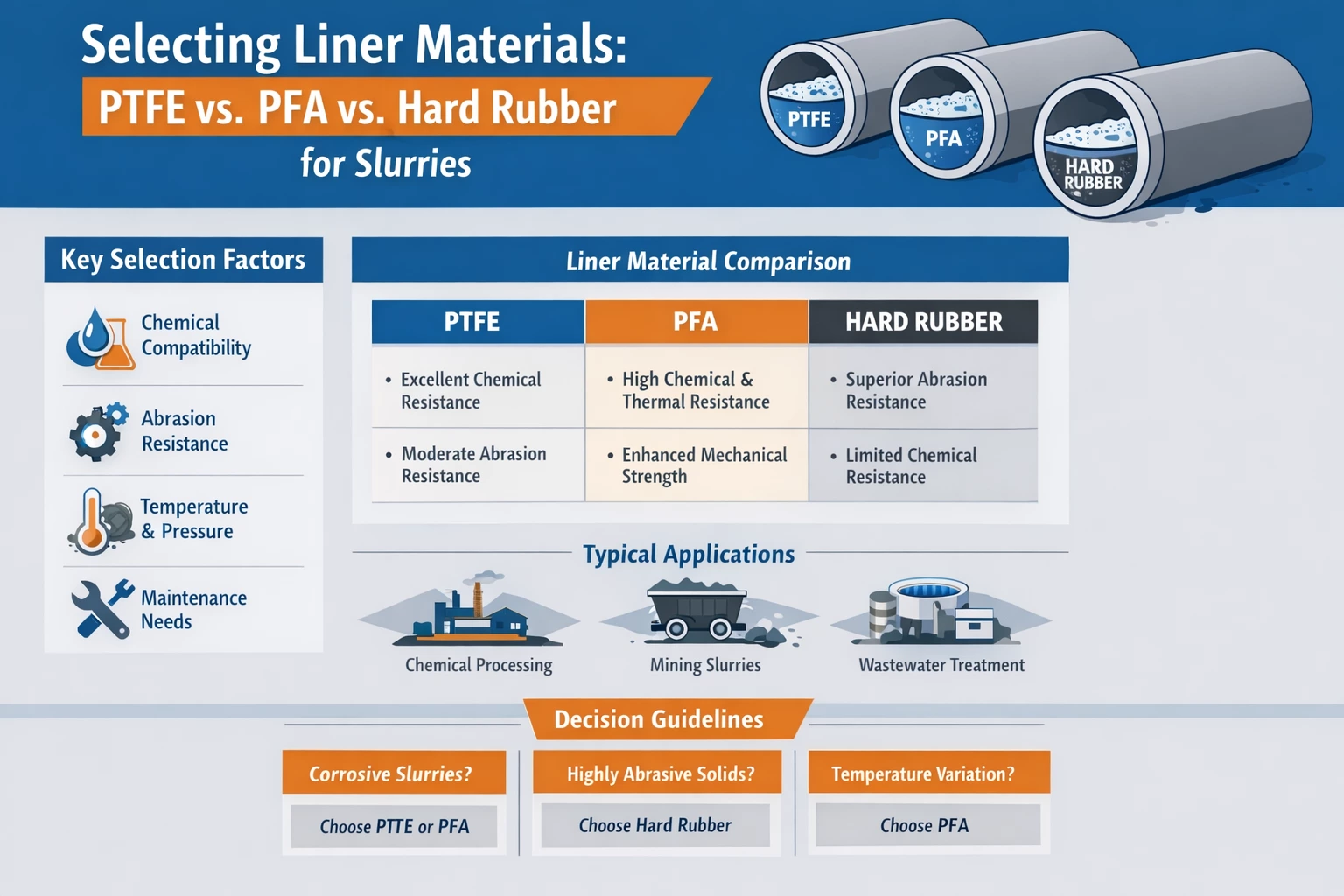

Among the most widely used liner materials for slurry applications are PTFE, PFA, and hard rubber. Each material addresses different process priorities, and misunderstanding their differences often leads to premature wear or unexpected downtime. This article provides a deeper, application-focused comparison to help engineers make informed decisions based on real operating conditions.

What Is a Liner and Why Is It Critical in Slurry Systems?

A liner is the protective inner layer that isolates the process medium from the metal body of pipes, valves, and instruments such as flowmeters. In slurry service, the liner must withstand continuous particle impact while maintaining chemical compatibility and dimensional stability.

Common failure modes caused by improper liner selection include:

-

Accelerated erosion from solid particles

-

Chemical attack leading to swelling, cracking, or delamination

-

Signal drift caused by material buildup or liner deformation

-

Unexpected leakage due to liner rupture

For slurry applications, liner performance often determines whether an instrument operates reliably for years or fails within months.

PTFE Liner: Maximum Chemical Compatibility, Moderate Abrasion Resistance

PTFE liners are widely used where chemical resistance is the dominant requirement. PTFE is nearly inert to most acids, alkalis, and solvents, which makes it suitable for chemically aggressive slurries.

What engineers often ask: Is PTFE suitable for abrasive slurry?

PTFE can handle mild to moderate abrasion, but it is not optimized for heavy solid loading or sharp particles. In high-velocity or high-solid slurries, abrasion may shorten service life.

Strengths and Limitations

PTFE offers a smooth, non-stick surface that reduces fouling and buildup, helping maintain stable measurement signals. However, its relatively soft structure means it may deform under high mechanical stress or sustained abrasion.

Typical Applications

-

Chemical reaction slurries

-

Acidic or alkaline process streams

-

Slurries where chemical corrosion outweighs mechanical wear

PFA Liner: Balanced Performance for Demanding Conditions

PFA liners are often described as an upgraded alternative to PTFE. They retain excellent chemical resistance while offering improved mechanical strength and thermal stability.

What engineers often ask: When should PFA be chosen over PTFE?

PFA is preferred when applications involve pressure fluctuations, temperature cycling, or stricter mechanical requirements alongside chemical exposure.

Strengths and Limitations

PFA liners perform better under mechanical stress and are less prone to cold flow or deformation. However, they come at a higher material cost and may be unnecessary for moderate service conditions.

Typical Applications

-

High-temperature slurry processes

-

Systems with frequent CIP or SIP cycles

-

Applications requiring both chemical resistance and dimensional stability

Hard Rubber Liner: The Abrasion Specialist

Hard rubber liners are designed primarily to combat mechanical wear. In slurry systems dominated by solid particles, rubber often provides the longest service life.

What engineers often ask: Is hard rubber compatible with corrosive slurry?

Hard rubber performs well in neutral or mildly corrosive environments but is not suitable for strong acids, solvents, or high-temperature processes.

Strengths and Limitations

Hard rubber absorbs particle impact and resists erosion effectively. However, its chemical resistance and temperature tolerance are limited compared to fluoropolymer liners.

Typical Applications

-

Mining and mineral slurry transport

-

Wastewater treatment (TSS / MLSS applications)

-

Industrial sludge handling

PTFE vs. PFA vs. Hard Rubber: How Do You Decide?

Key comparison perspectives include:

-

Chemical exposure: PTFE and PFA outperform rubber

-

Abrasion severity: Hard rubber excels under heavy solids

-

Temperature variation: PFA handles thermal stress better

-

Maintenance strategy: Rubber often offers longer wear life but limited chemistry

In many real projects, liner selection is driven by the dominant failure risk rather than theoretical material limits.

Impact of Liner Selection on Measurement Accuracy

For instruments such as electromagnetic flow meters or Coriolis flowmeters, the liner material affects:

-

Signal stability

-

Measurement repeatability

-

Long-term calibration drift

A liner that degrades unevenly can introduce subtle errors long before visible failure occurs.

Final Perspective: Designing for Reality, Not Theory

Selecting between PTFE, PFA, and hard rubber liners is not about choosing the most advanced material, but it is about matching material properties to actual process conditions. Over-specifying increases cost without benefit, while under-specifying leads to premature failure.

By evaluating slurry composition, operating conditions, and maintenance capabilities together, engineers can achieve longer service life, more reliable measurements, and lower total ownership cost.

Common Selection Questions Engineers Care About

Here are some frequently asked questions that you may be interested in:

How does slurry particle size affect liner choice?

Larger and sharper particles increase abrasion risk, favoring hard rubber. Fine particles with aggressive chemistry may favor PTFE or PFA.

Does flow velocity matter?

Yes. Higher velocities increase erosion. Rubber liners typically tolerate higher velocities in abrasive slurries.

Is liner thickness important?

Absolutely. Thicker liners improve wear resistance but may affect internal diameter and measurement sensitivity in some instruments.